Flanges serve several functions in the plumbing system. For instance, depending on the context, they can aid in preventing the leakage of water and other fluids. While Stub Flanges may be the only viable option in some situations, particularly with high-pressure plumbing, they also provide advantages that other options lack.

Cost-Effective

The three primary benefits are:

- The design of cost-effective flanges.

- The use of a 3LPE Coated Pipe.

- The absence of welding.

As a first point, they are not limited to the same Stub End and Angle Ring materials. This allows the exterior components to be made from the same materials as the inside pipes. Second, they permit 360° of rotation, guaranteeing a solid connection and shortening upkeep times. And lastly, they require little in the way of setup or upkeep. Products like these might serve as guides when you’re unsure what flange you need.

Easy To Set Up

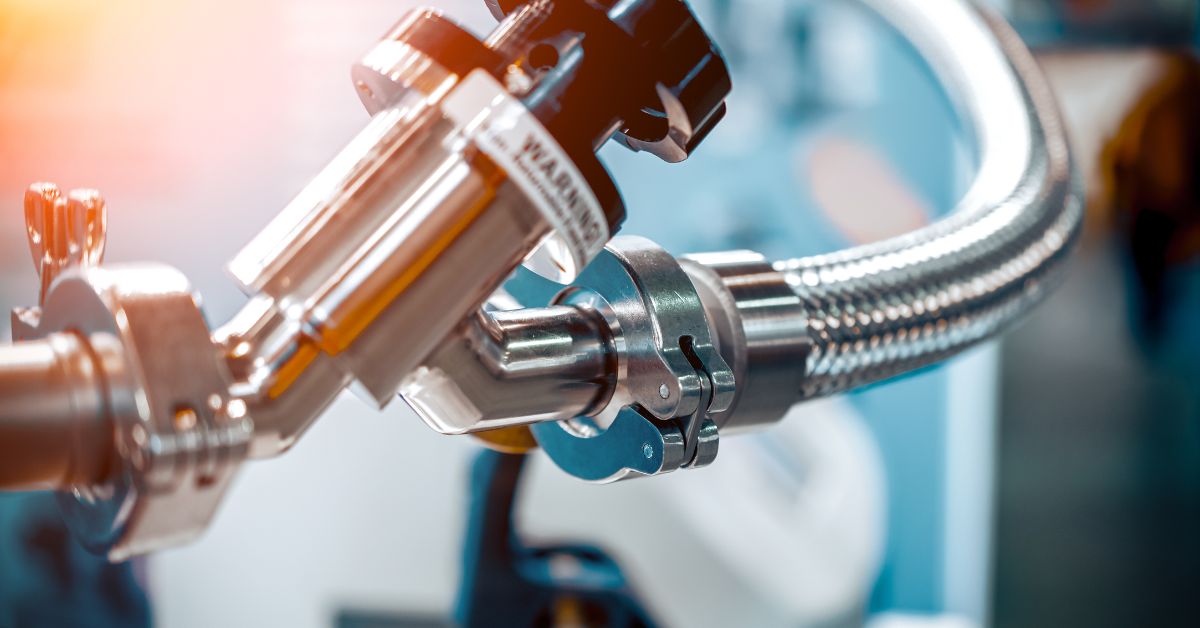

While installation of flanges is not particularly challenging, it is recommended that a competent worker wear protective gear and use caution. The flange covers must be a perfect fit for the flanges; otherwise, the pipes could be damaged. Flange covers come in various styles and sizes, each serving a specific purpose. You should consult the manufacturer’s specifications and instructions when deciding which flange cover is best for your application. Wearing protective gloves during installation will protect your hands from any injuries, including cuts and scrapes.

Slip-on and lap-joint flanges are common. Slip-on flanges are standard and come in several sizes. This flange may handle different styles and materials. Flanges can have stress-release test caps. This method helps link high-pressure pipes. Use this flange if you often disassemble your pipeline or have limited space.

Push-tite flanges are similar. Gaskets in this flange’s lip keep pipes in place. It can also handle heavier Pipes. These models are made of chemical-resistant elastomers. Four screws stabilize flanges. After installation, these flanges can link pipes.

Reliability

Flanges’ dependability is crucial to the protection of workers in manufacturing environments. Protruding rims, or flanges, offer structural support to an item. Courses in flange integrity provide students with a theoretical grounding in flange integrity and hands-on experience creating and dismantling flanged connections using conventional bolt-up techniques. Students will learn how to safeguard and preserve flanges for containers and pipes. Flange training is helpful for anyone in the engineering or maintenance fields.

The load capacity of a flanged junction is greater than that of a bolted joint. This means flanges can support more weight than bolted connections when used in an assembly. For this reason, flanges outlast materials like metal and plastic. Higher loading capacities are possible without compromising flange durability because of the outer gasket compression element’s resistance to flange rotation.

Conclusion

In addition, financial constraints will heavily influence the decision as to which flange is the best or most appropriate. Here are several applications where flanges excel. While some Stub Flanges are more affordable, some might put a severe dent in your wallet. As the adage goes, however, quality has no immediate value but delivers dividends over time, so spending more on a high-quality flange will pay off in the long run.